So you’re ready to print your job, but you want white ink or metallic gold lettering, how do you print those specs? There’s so many different ways to print work, and each has it’s own benefits. This week we’ll talk about some of the printing methods available and why you might chose one over the other.

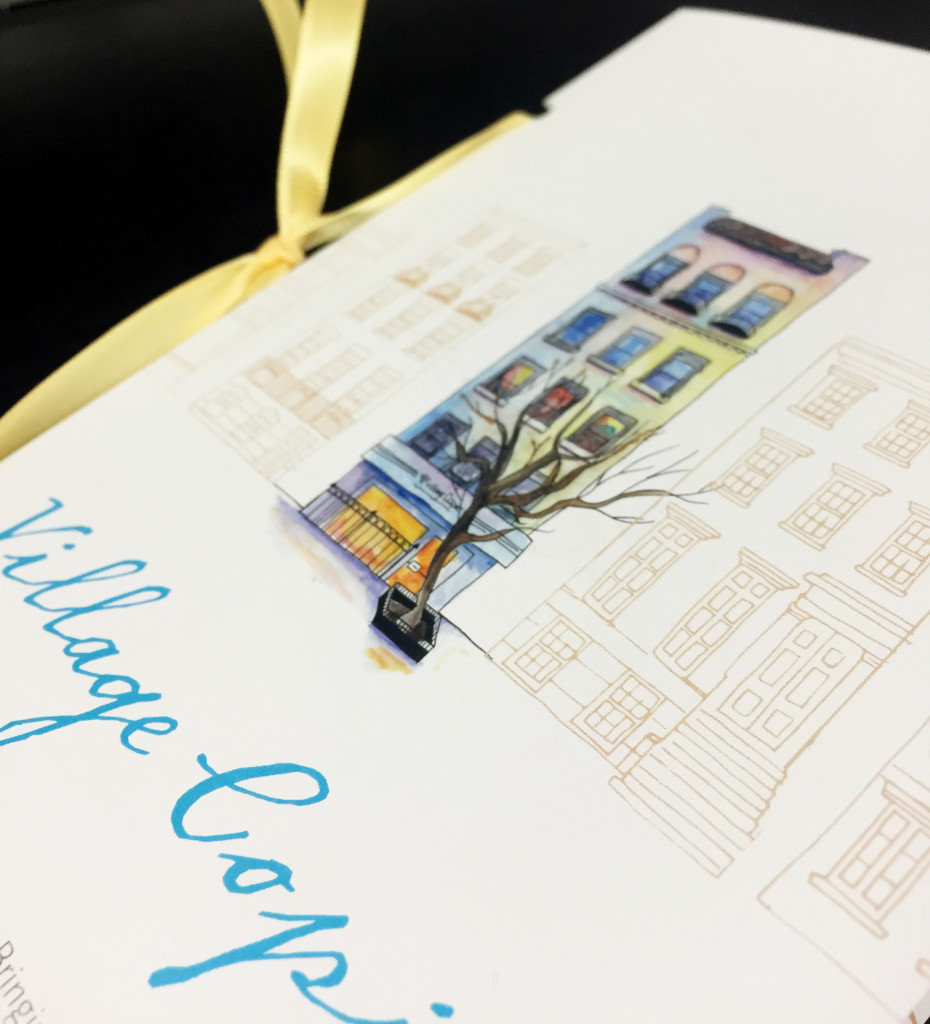

Digital Printing

Probably the most familiar method of printing, digital refers to methods of printing from a -based image directly to a variety of media. It usually refers to professional printing where small-run jobs from desktop publishing and other digital sources are printed using large-format and/or high-volume laser or inkjet printers. It allows for on-demand printing, short turnaround time, and even a modification of the image (variable data) used for each impression because a plate does not need to be made to create a print.

Digital Off-Set

Offset printing works by transferring ink from a plate to a rubber sheet, which then rolls the ink onto paper, vinyl or other surface. Offset printing is typically the best choice when you’re printing more than 500 to 1,000 pieces because it allows you to print larger sheets and many pieces quicker than digital printing presses.

Screen Printing

Screen printing is a stencil method of print making in which a design is imposed on a screen of polyester or other fine mesh, with blank areas coated with an impermeable substance. Ink is forced into the mesh openings by a squeegee and onto the printing surface during the squeegee stroke. As the screen rebounds away from the substrate the ink remains on the substrate. One color is printed at a time, so several screens can be used to produce a multi-colored image or design.

Lettpress Printing

Dating back to the 15th Century, letterpress printing is done by inking a plate with a raised surface of type or images and pressing this surface into a sheet of paper, creating a beautiful de-bossed impression. Letterpress printing provides a wide range of production choices, but it’s strengths are crisp lines, patterns, and typography.

Foil Stamping

Foil stamping is the application of pigment or metallic foil, often gold or silver , but can also be various patterns or what is known as pastel foil which is a flat opaque color or white special film-backed material, to paper where a heated die is stamped onto the foil, making it adhere to the surface leaving the design of the die on the paper.

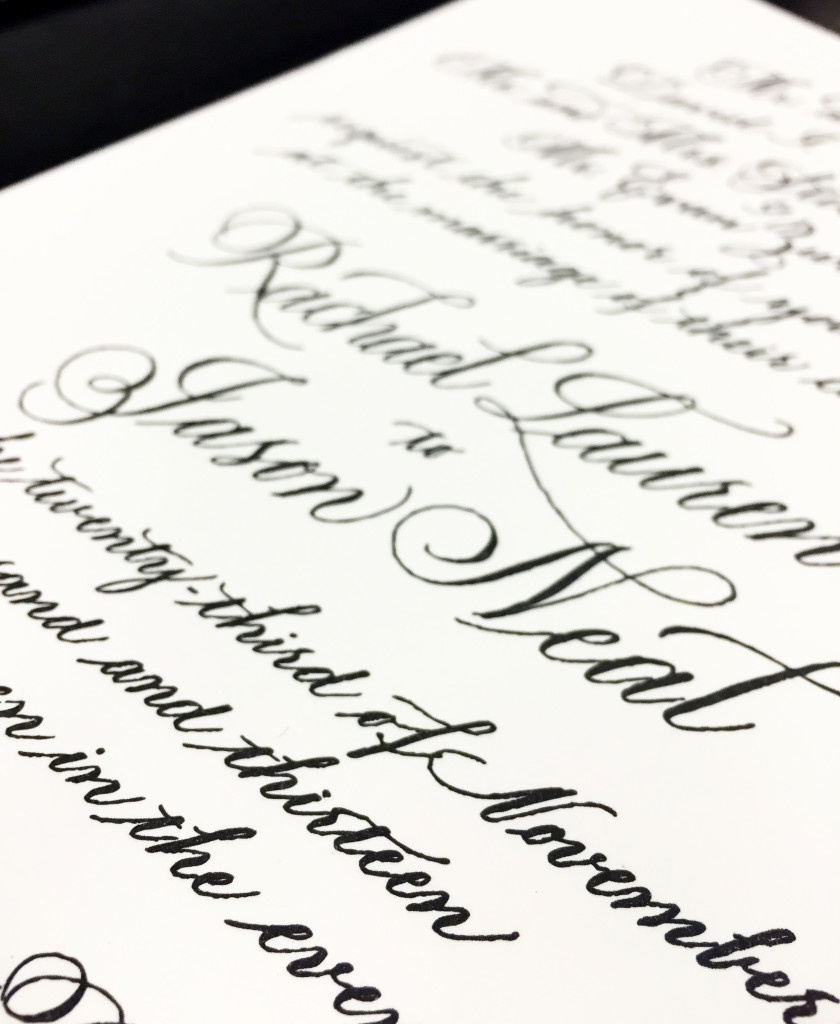

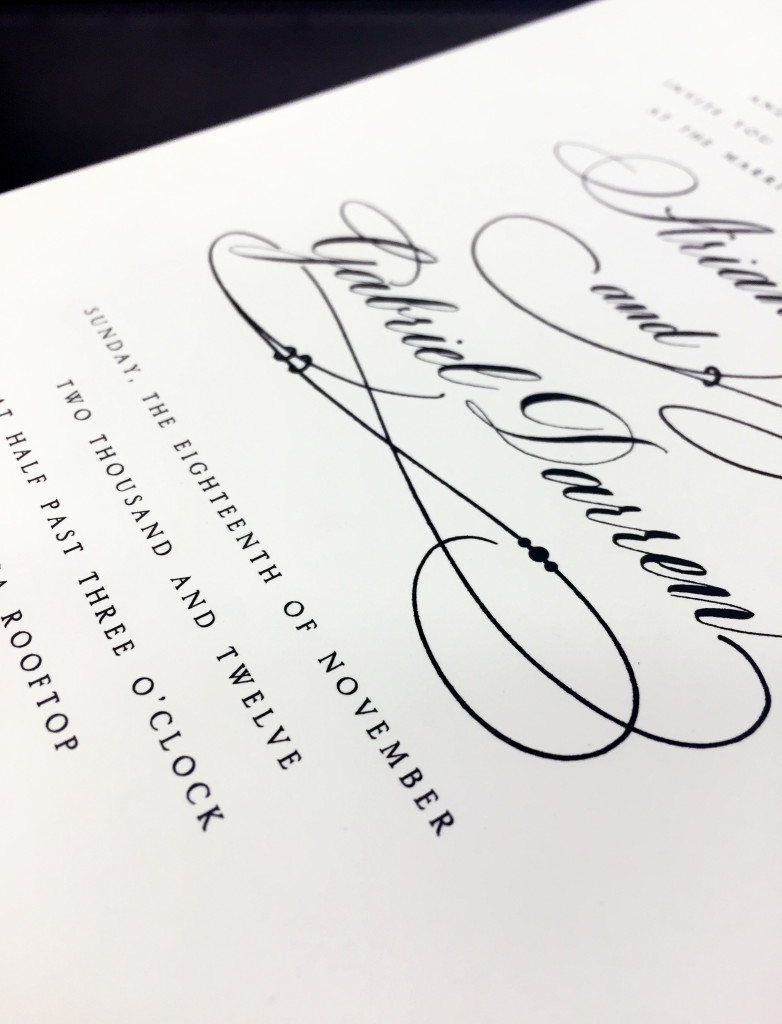

Engraving

As a highly skilled craft dating back to the 16th century, engraving conveys an unspoken message of distinction and timelessness. Running your fingers over a piece of engraved stationery reveals the textures unique to engraving — finely detailed, raised letters with slight indentations on the reverse side of the paper. There is no substitute for true engraving. An image is etched into a copper plate and sent through a press, forcing part of the paper into the etched cavity of the die, creating inked, raised surfaces in the paper. You can tell if something is truly engraved by the bruising on the back of the paper.

Thermography

One of the most affordable types of printing, thermography involves adding a resinous powder to the printing ink. When the combination is heated and dried it creates a slightly raised effect. Sometimes referred to as “imitation engraving”, thermography produces an effect similar to but not quite as elegant as engraving. Because it does not require the creation of an engraved plate, thermography is less expensive and faster than engraving.

Great post! Digital offset printing works best with larger products while maintaining the quality of the logo, etc. Thanks for sharing!

Thanks Catherine!